Here, images of component features are evaluated via image processing and the current component position is determined. The deviation of each component from a taught component position is then transmitted to the control card as a so-called process transformation and thus the position of the drawn laser path is adapted precisely and reliably to the respective component position.

RAYGUIDE MATCH also always includes RAYGUIDE CLICK & TEACH and the calibration routine for the camera contained therein.

The control of the necessary lighting elements is also an integral part of RAYGUIDE MATCH. Here you can choose either a 2-, 4- or 8-channelillumination controller.

If RAYGUIDE MATCH is used with the pre-focusing deflection units from RAYLASE such as the AS-FIBER series plus RAYSPECTOR MODULE, then in principle one has the unique possibility of also using features for detection, which lie in a different focal position than the actual component contour to be processed.

The architecture of RAYGUIDE MATCH allows you to build a recognition job in a very modular way and thus adapt it to the recognition task at hand.

The following detection functions are available:

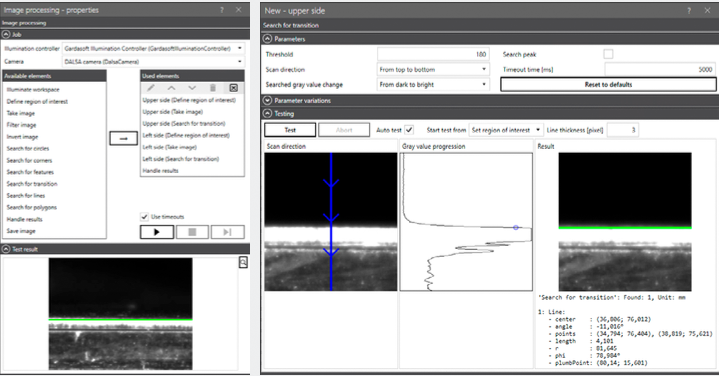

Grey value transitions: This allows to determine very precise ordinates of features with sharp grey value transitions.

Lines (straight edges): Detect two straight ed- ges and you have already determined offset and rotation. Various algorithms are available here to achieve a reliable recognition result depending on the situation.

Corners: Detect corners (with angles between 45° and 120°) and thus receive one coordinate per corner. Slightly rounded or chamfered corners can also be recognised.

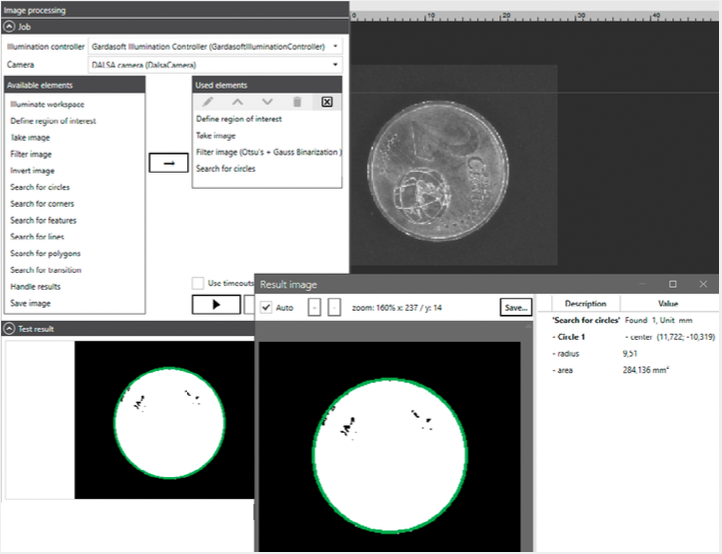

Circles: This can be used to detect holes, circular openings or even cylindrical structures on a battery, for example.

Polygons: This can be used to identify triangular references, for example.

"Features“: Recognition of objects (compared to a reference image) based on the object corners and their specific environments.

A result handler combines the results of the individual searches to calculate offset and rotation for the transformation.

Using the process transformation offered by the SP-ICE-3 control card allows position adjustment without having to send the original process file to the control card each time, thus avoiding unnecessary upload times.