electrode manufacturing for

battery cells

Cutting electrode foils

Which laser deflection unit delivers top performance when cutting electrode foils?

In light of the recent increase in recalls of cars and battery systems in the electromobility segment, German machine manufacturers are homing in on quality in an effort to stimulate new growth in this market. Their objective is to produce superior cutting edges when manufacturing electrodes for battery cells to achieve outstanding quality “Made in Germany” and combat international competition, especially from their mighty Asian rivals. Unfortunately, the production methods and standards that battery cell factories use for lithium-ion battery foils do not yet match those used in the automotive industry. The performance and life of these cells depend on the current quality levels being increased. Which means that achieving this is in the interests of the car manufacturers who want to ensure that recalls of e-cars soon become a thing of the past.

In conjunction with ambitious machine manufacturers, the latest laser technology, with its highly innovative scanners, has the potential to create the urgently needed quality standards for the automotive area, while also helping to ensure the necessary speed essential to battery cell factories.

WHY ARE FOILS NEEDED IN BATTERY CELL PRODUCTION?

Three cell formats are currently used in the production of lithium-ion batteries for electromobility – pouch cells, cylindrical cells and prismatic cells. Regardless of cell type, the smallest unit of all lithium-ion cells consists of two coated foils, known as electrodes. One is a copper foil for the anode, while the other is a coated aluminum foil for the cathode. A microporous separator is also required to keep the electrodes separate from each other and through which the ion-conducting electrolyte can flow between the two electrodes.

Optimal laser cutting of electrode foils

Before

After

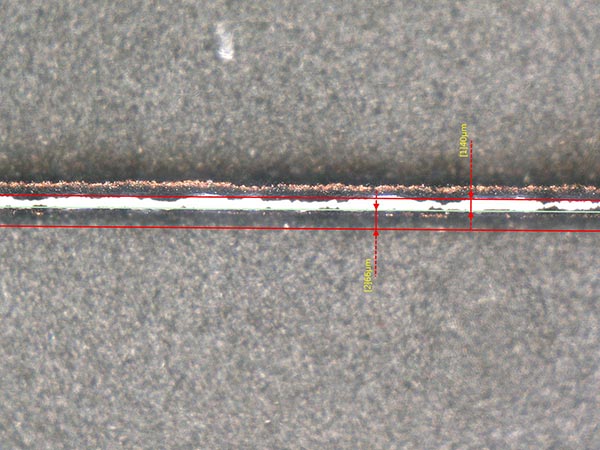

The microscopic image of the laser cutting edge shows a graphite anode, coated on both sides, with a thickness of 260 μm. Here you can clearly see how the coating has been burned away and the cut is ragged, compared with the clean cutting edge achieved with the AXIALSCAN II 50. Source: Sonplas

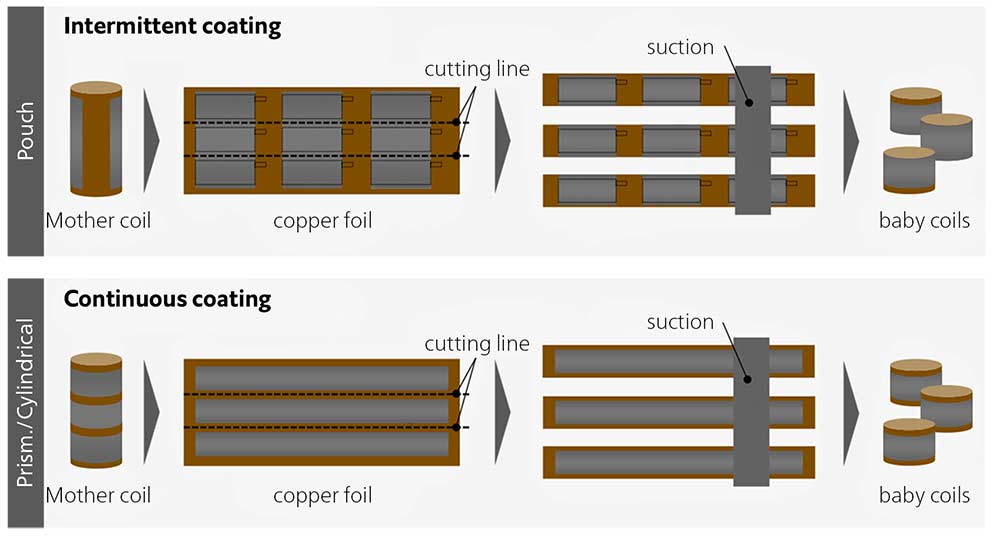

During the manufacturing of electrodes, carrier foils made of aluminum and copper are coated with electrode material on coils known as “mother coils”. These are subsequently divided into “baby coils” to create the desired cell format.

Next, the baby coils are cut at the edge and the individual electrode sheets are cut out. Modern laser systems offer clear advantages in this process. For example, a deflection unit can be used to ensure a high-quality cut through the coating, as well as fast, precise creation of the relevant electrode foils by means of contour cutting. Florian Thalhofer, development engineer at Sonplas: “Right now, we’re focusing on pouch cells in particular, as these enable the highest energy density in electric vehicles.”

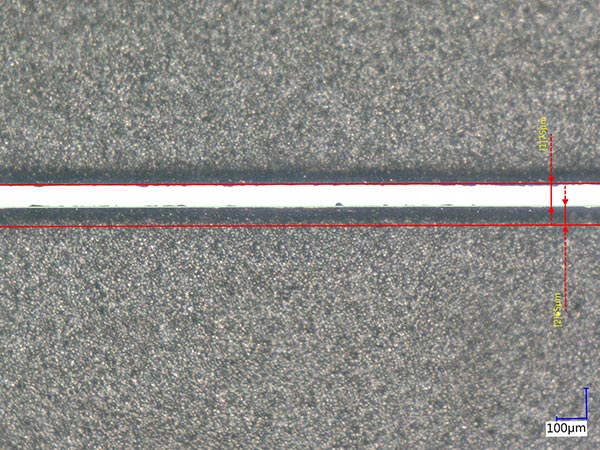

A laser cutting edge on a cathode with a thickness of 230 μm and a lithium nickel cobalt manganese oxide coating. The difference in quality is unmistakable when the right process parameters are selected and the AXIALSCAN II 50 is used. There are no welding beads and the heat affected zone is reduced. Source: Sonplas

It‘s all about being fast, clean and flexible

To increase productivity, the battery foils are usually cut and the individual electrodes of pouch cells (or other cell types) are usually created from running baby coils. This presents some huge technical problems. Florian Thalhofer knows the difficulties involved all too well: “The real issues arise because of a combination of different challenges. We have a very high cutting speed of over 1 metre per second. And the electrodes must not be contaminated in any way. Especially not with particles larger than 10 µm. Otherwise, the separator foil won’t be easily penetrated. We also need a system that allows us to process various geometries and shapes without having to modify the equipment – such as the largest standard electrodes on the market in the scanning field of 700 x 700 mm”. It‘s a highly complex process, requiring the greatest precision at top speeds as well as the ability to be modified. Modern laser cutting systems are perfectly equipped to handle this task.

Wear-free, position accuracy, unmatched speed

With the corresponding software and exact consideration of web speed, laser deflection units can perform electrode cutting with position accuracy and at unrivalled speeds. They can also handle the recent increase in foil thickness from 100 µm to over 200 µm and thus ensure the mechanical sensitivity of the electrodes. Because thicker electrodes are more difficult to cut.

The AXIALSCAN II 50 offers precisely the high-quality process that is required for this task and which has huge benefits compared with mechanical punching tools. Contact-free, and therefore wear-free, the laser is also more cost-efficient in the long term.

Sonplas software engineer Manuel Streifeneder next to a roll on the demonstration line. This process is used during the cutting of electrode sheets. The electrode foils are unrolled, cut with the laser and rolled up again or stacked individually.

Laser beam deflection units are strong on quality

The individual requirements of the customer process, as well as the materials and material strengths used to determine which particular system configuration of a deflection unit is suited to which job. Sonplas GmbH, the expert in special machine construction based in Straubing/Germany, has focused on enhancing the quality of cutting edges in electrode foil production. As Florian Thalhofer explains: “One of our main goals was to reduce the HAZ (heat affected zone) – the area within which the material is affected by the heat of the laser. We also wanted to prevent burnback (where the coating is burned away) and burr formation from occurring during cutting. In addition, we wanted to reduce both the number and size of particles”.

Innovative laser deflection units meet all of these requirements. They offer high flexibility in terms of processing field size. Wolfgang Lehmann, Product Manager at RAYLASE, explains:

“The larger the processing fields, the greater the requirements in terms of minimizing spot size and the higher the speed at which the process runs”. Using the right laser deflection units has been very beneficial for Sonplas. According to Paul Birkeneder in the Sonplas Sales department: “Improved cutting of electrode foils means that our battery cells have a longer life”. At present, the company is working on defining and optimising measurable quality criteria – in other words, a method for generally evaluating the quality of electrode cuts.

Therefore, it makes sense for customers to involve RAYLASE in the design of their machine configuration to address these challenges from the outset. In this way, they can ensure the best possible configuration of their laser system and deflection units to enhance productivity and quality, as Sonplas has done.

RAYLASE AXIALSCAN II-50

With its mirrors for a 50 mm beam size, the AXIALSCAN II-50 can generate an exceptionally small laser spot diameter, even in large processing fields. This ensures a very clean and straight cutting edge in electrode foils without the burnback. In addition, the extremely light yet stiff deflection mirrors enable highly dynamic responses, so that even 90° changes in direction during foil cutting can be executed without debris particles, burr formation or burnback.

The deflection unit is also supported by SP-ICE-3 control electronics and the new RAYGUIDE software, both from RAYLASE. These enable a range of functions with real-time capability, specially designed to meet the requirements of battery cell production. For example, RAYGUIDE laser software offers an optimised customer interface with the control electronics and, if required, an intuitive yet highly functional process configuration interface. It clearly visualises the processes to be executed and indicates when they are executed with a position-accurate time-stamp. In addition, the control electronics are also capable of exact consideration of line speeds (detected by encoders) – even during speed deceleration – and of performing cuts in precise positions. This function is known as MOTF – marking on the fl y – and it enables cutting while the mother or daughter rolls of foil are running.

Upper Bavaria meets Lower Bavaria

“Using the laser scanner enables a very good aspect ratio, or a very large working field with a simultaneously small laser spot size. This gives us a huge amount of flexibility, in particular in terms of geometry and electrode sizes”. The next goal the company from Lower Bavaria has set itself is to use a variation of the laser configuration to increase throughput while maintaining the high cutting-edge quality of the battery foils.

RAYLASE works closely with several machine manufacturers in the automotive industry. In the area of foil cutting for battery cell production, RAYLASE is currently collaborating closely with Sonplas GmbH, based in Straubing in Lower Bavaria. The company has over 300 employees, 60 percent of whom are engineers, who have been planning, assembling and maintaining special machines and inspection technology for the automotive and aerospace industries for almost three decades. In particular in the areas of electromobility, hydrogen, hydroerosive grinding, fuel injection technology, electronics, mechatronics and hydraulics, the in-house Research and Development department are continually setting new standards. Since 2020, Sonplas has focused on battery production, and specifically on improving quality in battery cell manufacturing.

The reason for this is that automotive standards are significantly higher than those in the consumer market. Florian Thalhofer, an engineer in the Research and Development department at Sonplas, explains the benefits of collaborating with RAYLASE: “By combining our expertise in battery cell production with the power behind the AXIAlSCAN II 50 laser deflection unit from RAYLASE – our top choice from the start – we succeeded in achieving very high-quality laser cutting of the electrode foils that have to be separated”. Sonplas managed to do just that on an initial test line, which it documented with many microscopic digital images. And it doesn’t stop there.

Sonplas is currently creating a demo system for customers to allow them to view and experience this leap forward first-hand. This union of expertise in special machine construction from Lower Bavaria with innovative laser deflection units from Upper Bavaria in the form of collaboration between the two research- based companies has the potential to improve the quality of foil cutting and thus of battery production many times over. In this way, it supports the very dynamic growth we are currently seeing in Europe, and in Germany in particular.

According to Paul Birkeneder: “Our vision is to enter the market dominated by Asian plant manufacturers and to support the emerging battery cell factories, especially in Europe, thus becoming one of the providers who deliver top quality”. High- quality battery production also makes sense from an ecological perspective, as it helps reduce the currently high scrap rates from production. And that is exactly what premium brand car manufacturers have been waiting for.

battery cells