3D-PRINT CERAMIC COMPONENTS (LCM)

WE SOLVE YOUR REQUIREMENTS

WE KNOW YOUR NEEDS

NEXT LEVEL ADDITIVE MANUFACTURING: 3D PRINTER LITHOZ CERAFAB WITH RAYLASE DEFLECTION UNIT FOR HIGH-PERFORMANCE CERAMIC COMPONENTS

Laser technologies are currently revolutionizing many traditional manufacturing processes, for example, in the areas of marking and cutting. But lasers have the potential to do much more. Using powerful deflection units from RAYLASE, for example, opens up some brand new possibilities in application areas which would not have been possible before.

One example of this is lithography-based ceramic manufacturing (LCM for short), a patented 3D printing technology for ceramic materials that enables fast, cost-effective manufacturing of high-precision ceramic components without geometric restrictions and with a density in excess of 99.4% T.D. LITHOZ, the multi-award winning spin-off from the Technical University of Vienna and holder of the patent for this LCM technology, chose RAYLASE for the deflection unit for one laser variant used in their machines. RAYLASE was also actively involved as a partner during the design of the control module.

This is three-dimensional printing without any waste and without the ridges that typically occur with other processes, completed within much shorter space of time and producing signifi cantly improved object hardness and smaller object sizes. These are just some of the benefits offered by the LCM process.

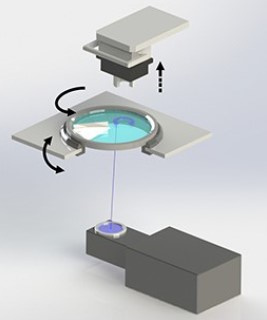

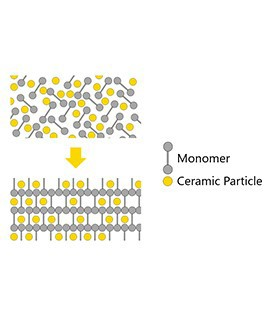

In the first step, a ceramic source material consisting of a photopolymer (such as acrylate or methacrylate, which effectively acts as a binder during the intermediate manufacturing stage) and ceramic particles are poured into a 3D printer (1). The laser beam is defl ected via the deflection unit onto the locations calculated by the CAD software (2) and hardens or polymerizes the binder (3), so that the desired object is built up layer by layer. Once 3D printing is completed, the binder is burned out of the component in a furnace, leaving only the ceramic particles behind. In the fi nal sintering step, the ceramic particles are compressed and the finished component is produced (4).

Benefits of LCM objects compared with other materials and processes:

- Heat-resistant to well above 1000°C

- High degree of mechanical strength

- Low material expansion

- Resistant to corrosion

- Resistant to abrasion and wear

- Low density

- Very hard

Why LITHOZ chose the 3-AXIS DEFLECTION UNIT for the handling of high-performance ceramic parts process

As illustrated in figure (2) above, the polymerization process requires the component that is to be constructed to be rotated 180°, and so the 3-axis deflection unit (5) works from bottom to top. This was made possible by the high degree of flexibility offered by the 3-axis deflection unit, even when it is integrated into complex and restricted environments such as a 3D printer.

The new design of the 3-axis deflection units enables extremely fast processing of various shapes and sizes in the relevant working fields with the smallest spot diameters. The deflection unit offers a focus range in Z-direction of more than 200 mm in a 300 mm x 300 mm field. The twin-shell design ensures low drift values thanks to optimized temperature management.

Lenses with optimized lens holders and scan mirrors are available for all standard laser types, wavelengths, power densities and processing areas. Custom solutions such as that found in the LITHOZ 3D printer are always possible.

The photopolymerization process

(1) The liquid source material (a suspen-

sion of ceramic powder and polymer-based

binder) is poured in.

(2) The laser reaches the material via the

3-axis deflection unit and the object is built up,

layer by layer, from the bottom up.

(3) The laser hardens the

photopolymer-based binder

in the required locations.

(4) In a furnace, the binder is burned

out of the ceramic and the finished

ceramic is sintered.

RAYLASE worldwide

Get expert advice for your application

Further applications