Battery production for electric mobility with laser technology

Battery cells are the core component of every battery. In the case of electric cars, up to 40 percent of the added value comes from battery cells. Unfortunately, there are no stan- dardised cell formats yet. The 7.9 million electric cars produced worldwide until 2019 contained lithium-ion batteries in three main cell formats: cylindrical, prismatic and pouch. The most common is the round or cylindrical cell as used in the Tesla M3. It is used flexibly in the form of many packs covering the entire underfloor compartment of electric cars. The prismatic cell used in the BMW i series - i3 and i8 - for example, is rectangular and considered the safest cell format. Pouch cells, on the other hand, are cheaper to produce, but can also be less safe as they are more flammable.

LASER TECHNOLOGY IS A KEY COMPONENT OF E-MOBILITY

On route to the mass market for e-mobility, it is not only German industry that needs innovative technologies for series production. Robust processes that can be quickly ramped up from today‘s low production volumes are in high demand. Laser material processing plays a significant role. Essential elements of this are the lasers themselves and critical system components such as laser deflection units, optics, sensors, quality monitoring and digital control systems. Laser material processing is a key component in manufacturing for e-mobility. This process is used in the manufacture of essential components, including among others the electric drive itself, the manufacture of battery cells, modules and packs, and finally the necessary power electronics. Laser material processing makes it possible to manufacture the battery in an efficient, contactless and affordable way at maximum capacity and with maximum flexibility at the same time.

Read more in the whitepaper

RAYLASE works closely with customers in the following three applications which form the core of electric mobility:

Application 1 - Laser cutting electrode foils for battery production

Much currently depends on efficient battery production in the industry since faster and more precise manufacture leads to enormous cost savings in production. Modern laser technology is proving to be an innovative driver from which electric mobility can only gain. The manufacture of lithium- ion battery cells essentially involves three production steps: electrode manufacture, cell assembly and cell finishing.

Electrode production and cell finishing can be carried out largely independently of cell type, while for cell assembly a distinction is made between pouch, cylindrical and pris- matic cells. Regardless of the cell type, the smallest unit of every lithium-ion cell consists of two electrodes, namely a coated foil for the anode (copper) and cathode (aluminium) and a microporous separator made of plastic that separates the electrodes from each other. In between is the ion-con- ductive electrolyte.

Read more about application 1 in the whitepaper

Application 2 - “Tab welding“ and “cell connector welding“ different cell formats

Another important application area for modern laser systems in e-mobility is the field of “welding”. It is known that a battery should fully charge as quickly as possible, have the highest possible charge capacity and the longest possible range. But wherever electricity flows, there is always electrical resistance. Under certain circumstances, these can drastically limit the efficiency of the battery. Especially when many individual small battery cells or submodules are connected in series to form a larger cell network such as a “pack” or “stack”, such small contact resistances can quickly add up to a large total resistance. And that should be avoided.

Read more about application 2 in the whitepaper

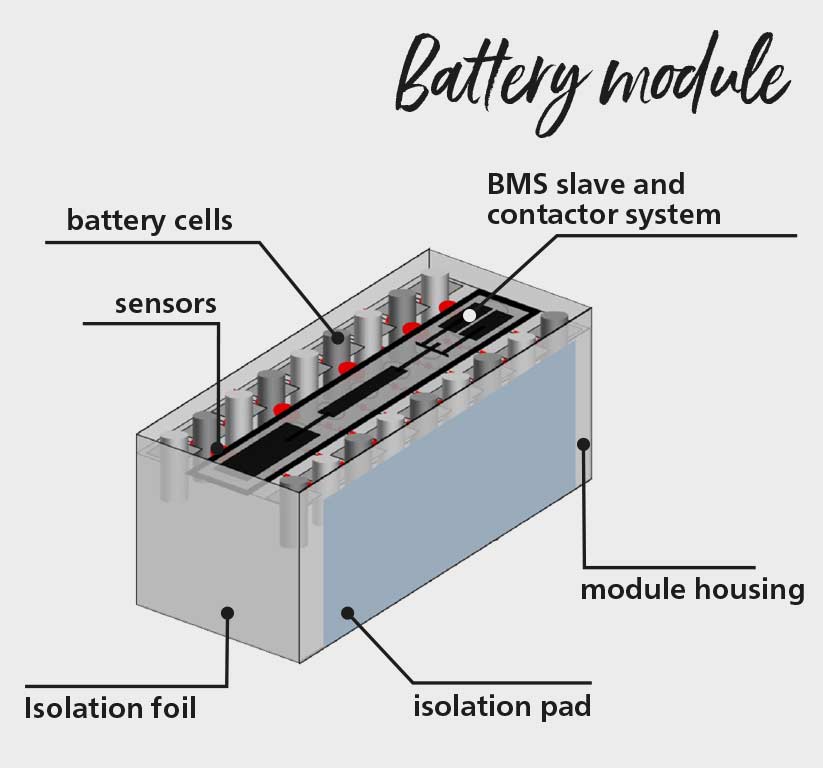

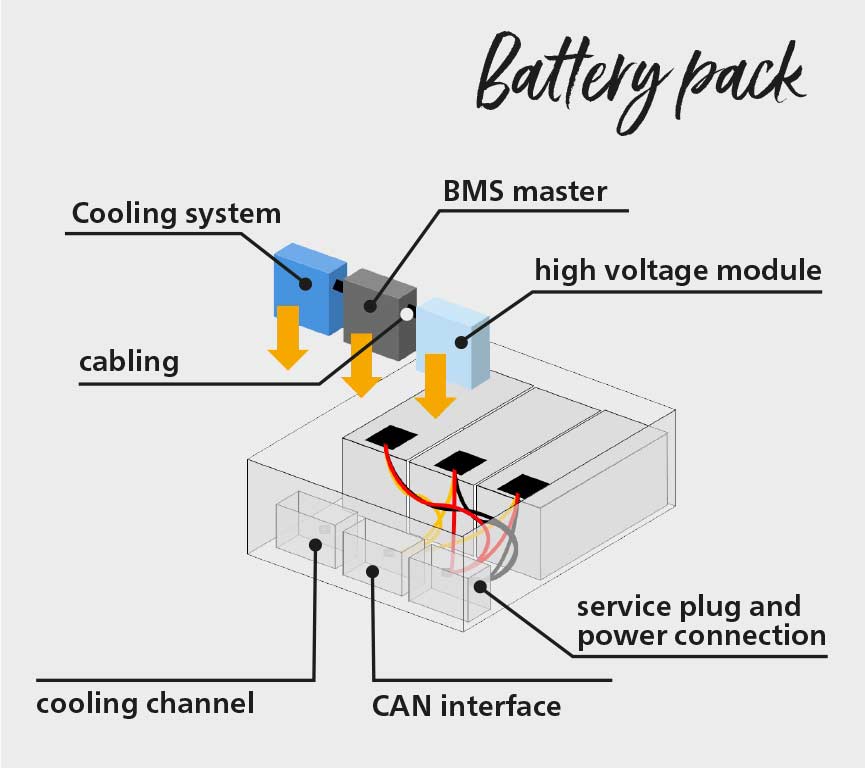

Application 3 - Laser welding aluminium components on battery packs

Another and no less important application area for laser deflection units on battery packs comprises the various welding applications on aluminium components. They are joined together and to each other using laser technology.

These sometimes very thin aluminium components place high demands on the welding process. Great flexibility is required to generate complex welding contours while simultaneously ensuring high positioning accuracy. The challenge is also to process very large laser process fields with just one laser unit with a very fine spot size.

Intelligent welding ramp functions on the control electronics ensure that the energy input into the join partners always produces a uniform welding result. The welding depth should always be constant and consistently monitored.

Read more about application 3 in the whitepaper